Aluminum Heat Treating by Coastal Foundry

Aluminum Heat Treating (A 356.2, 356.1)

Heat treating (tempering) of aluminum alloys is carried out to vastly improve the stability and mechanical properties of aluminum alloys

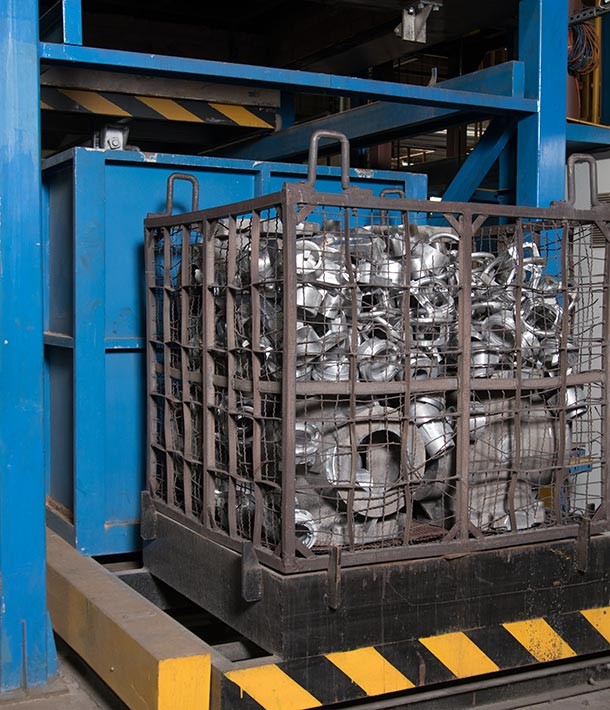

Coastal Foundry has recently commissioned a new heat treating (tempering) plant at its factory in Houston. The system is designed and equipped specifically for aluminum alloys and can treat up to 2,000 lb. per load. Two separate furnaces were purchased, one a Drop Bottom Solution Heat Treating and the other a Bogie Hearth Aging Furnace. Both furnaces are automatic, are powered electronically with state of the art diagnostics and can maintain temperatures to within + / - 3 ℉, well within the ASTM Standard of + / - 10 ℉. For maximum effect quenching can be done within 15 seconds

Certifications are provided with all products treated. Coastal Foundry is happy to accept contract work.

Below are the tempering designations. All “T” heat treating can be performed:

F As cast

T5 Age only (precipitation)

T6 Solution heat treat, quench and age